|

Block the front wheels and place transmission

in park or reverse.

Use a jack and raise the rear of your car.

PLEASE "DO" use jack stands for safety.

The above photo (fig.1) shows the complete

bar removed from the car.

To remove the track bar there are two bolts.

The right side looks like fig.2. This bolt

uses a 18mm wrench or socket. |

|

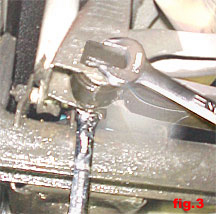

The left side of the track bar uses a

18mm wrench, as there is no room for

a socket on the back side.

I used a "GearWrench" on the back side

and a 13/16" box end wrench on the front

side. See figure 3. |

|

The track bar off of the car. You can see in

fig 4 where hard cornering has started to bend

the bar just a little. |

|

The first step to making the track bar stronger,

is boxing it in. If you do not want to do this,

skip to step 9.

I bought a piece of steel 1/8" thick, 1" wide

and 44-1/2" long. |

|

You will want to clean all of the paint off

of the edges of the track bar before welding.

Lay the piece of steel on the track bar,

end to end. |

|

Clamp the piece of steel into place.

You will want to "stitch" weld the steel

to the track bar. |

|

This shows what "stitch" welding the piece

of steel to the track bar looks like. Weld in

one area, go to another area to weld, etc.

This lets the welds cool. Stitch welding

helps keep the track bar from warping. |

|

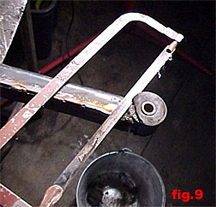

To remove the old rubber bushings, cut

the flange off one side with a hack saw.

Do this to both ends of the track bar. |

|

Use heat to warm up the bushings. You can

also use a propane torch for this job, you

don't need an oxyacetylene torch as I used here.

You don't need to catch it on fire. You want it

to heat up the bushing. It will swell up the

rubber and make it want to slide out.

NOTE: It is best to wear gloves!

NOTE 2: You also can just drill out the

rubber. Put the track bar in a vise and

drill into the rubber multiple times, until

the bushing is destroyed. |

|

I use a bucket under the job to catch any

melting rubber. It can be real messy.

After it seems heated enough, you can try

tapping the rubber out with a small hammer.

After the rubber is out, clean the track bar

with solvent or brake cleaner. Use rags that

you will be throwing away.

|

|

I sanded my track bar and painted it with

spray can "bedliner" paint. Or you can use

regular paint or have it powder coated for

something really nice.

Add two of the poly bushings to each end

of the track bar. |

|

Add the special green poly lube to the sleeve

and slide it into the track bar bushings. |

|

Also add the special green poly lube to the

outside area of the track bushings as shown

in figure14. |

|

After installing the bushings to both ends

of the track bar, reinstall it into the car.

Tighten both bolts and nuts, your done! |